100% found this document useful (1 vote)

1K views3 pagesCoco Flour Flow Chart

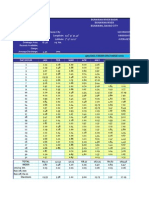

The document outlines the standard operating procedure for producing coconut flour and coconut oil, including procuring coconuts, grading, de-shelling, paring, pre-cutting, washing, sterilizing, disintegrating, squeezing milk, drying, packing coconut flour and oil, and storing the final products. Key steps involve removing the husk and shell, cutting the coconut into pieces, extracting coconut milk, drying the flour to less than 2% moisture, and packing the flour and oil in food grade containers for storage.

Uploaded by

William PulupaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

1K views3 pagesCoco Flour Flow Chart

The document outlines the standard operating procedure for producing coconut flour and coconut oil, including procuring coconuts, grading, de-shelling, paring, pre-cutting, washing, sterilizing, disintegrating, squeezing milk, drying, packing coconut flour and oil, and storing the final products. Key steps involve removing the husk and shell, cutting the coconut into pieces, extracting coconut milk, drying the flour to less than 2% moisture, and packing the flour and oil in food grade containers for storage.

Uploaded by

William PulupaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd