1441677-A Rev Level K PPAP Submission

Uploaded by

Axel Mata1441677-A Rev Level K PPAP Submission

Uploaded by

Axel MataInitial Sample Report

Customer Site RF Issue

Titan Engine Cooling Jamestown

Commodity or Project Buyer SQAD Engineer

Part number Part description Drawing number Issue-level

1441677-A Plateside 144T022 K

Supplier name Supplier Site (location) Issued by Date

P&G Steel Buffalo N.Y. Brian Riemer 3/10/2020

File content: Status

PSW

First page (PSW) of Initial Samples reports of suppliers sub-components

Mapped Drawing

Dimensional Report

Sample parts

Material-cert.

Logistics and packaging validation (packaging instruction sheet + label on packaging).

Toolings

Tooling drawings including spare part list

Defect catalogue

Report into IMDS database

Full traceability of IS (Id-marking of IS part must correlate with dimensional report)

*Other1

*Other2

* = Other documents if requested in the [Link]

First page (PSW) of Initial Samples reports

of suppliers sub-components

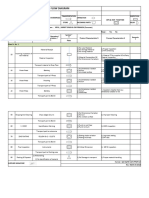

PPAP INFORMATION FORM

DOCUMENT NUMBER: CPTEC144T022

CUSTOMER NAME: TitanX Engine Cooling

CUSTOMER PART NO: 1441677-A

PART NAME: Plateside

LATEST PRINT REV: K

REV DATE: 10/21/2019

SUPPLIER CODE: 47606

ORIGINAL ISSUE DATE: 03/10/20

DOCUMENT REV DATE: 03/10/20

DOCUMENT REV LEVEL: A

Inspection Key

Process Flow Diagram Product Name: Plateside

Changeover Key

P=Product A=Automatic Doc rev: A

T=Tooling M=Manual Part No: 1441677

S=Software V=Visual Part Rev: A

D=Dunnage Q=Quality Audit Prepared By: Brian Riemer

L=Label

Print Reference

Print reference

Scrap/ Contain

Changeover

Store/Get

Significant Process Significant Product

Rework

Inspect

Critical

Operation Description Characteristics Characteristics

Move

Op-

Fab

Seq. (Inputs) (Outputs)

V Receiving Material Tag Must match shipper

Receiving Material Weight Must match shipper

Receiving Material thickness 2.0 Thick

Material Certification

Receiving AA 3003 with 4343 1-side clad 4%

Store in protected proper No damage caused by move or

Store components location storage, No damaged boxes

containers.

2 Pull Components from inventory Traveler

Material cleanliness No dirt,excessive oil, road crud,

V

rust or white rust.

P 1-

MV

T Stamp 63 Print 144T022

End tab to center of radius 1 Print 144T022 18.9 +/- 0.8

End tab to center of radius 2 Print 144T022 7.5 +/- 0.8

Radius 3 Print 144T022 R3 +/- 0.8

Datum A to tab 4 Print 144T022 13.7 +/- 0.5

Tab height 5 Print 144T022 5.5 +/- 1

End tab to center of radius 6 Print 144T022 5.7 +/- 1

Radius 7 Print 144T022 R3 +/- 0.8

Leg Height 8 Print 144T022 10 +/- 0.8

Straightness 9 Print 144T022 u 0.2

Radius 10 Print 144T022 2X R1.5 +/- 0.8

Part width 11 Print 144T022 52 +/- 0.8

Dimple height 12 Print 144T022 0.4 +/- 0.15

Dimple to dimple 13 Print 144T022 26 +/- 1

Hole Diameter 14 Print 144T022 n10 +/- 0.8

Dimple length 15 Print 144T022 14X 15 +/- 0.8

Datum C to hole ("C" dim) 16 Print 144T022 558.3 +/- 1

Datum C to end tab ("B" dim) 17 Print 144T022 858.3 +0.5 -1.2

Datum C to tab end 18 Print 144T022 2X 88.5 +/- 0.8

Datum C to end tab 19 Print 144T022 2X 150 +/- 0.8

N/A 20 Print 144T022 8X 30~ +/- 1~ 0'

N/A 21 Print 144T022 4X 15.4 +/- 0.8

Datum C to centerline 22 Print 144T022 308.7 +/- 0.8

N/A 23 Print 144T022 131.9 +/- 0.8

N/A 24 Print 144T022 131.9 +/- 0.8

Leg Height 25 Print 144T022 10 +/- 0.8

Radius to radius ("A" dim) * 26 Print 144T022 * 843.3 +0.5 -1.2

Flatness 27 Print 144T022 0.2 / 100

Flatness 28 Print 144T022 c 1

End tab to middle tab 29 Print 144T022 12 +/- 0.8

Middle tab width 30 Print 144T022 9 +/- 0.8

Cutout width 31 Print 144T022 2 X 2.5 +/- 0.8

End tab width 32 Print 144T022 2 X 7 +/- 0.8

Edge to cutout 33 Print 144T022 2 X 19 +/- 0.8

Edge to tab 34 Print 144T022 2 X 5.5 +/- 0.8

End tab length 35 Print 144T022 2 X 2 +/- 0.3

Radius 36 Print 144T022 2X R Full

End tab to radius 37 Print 144T022 25.9 +/- 0.8

Part edge to tab edge 38 Print 144T022 2X 6.5 +/- 0.8

Tab width 39 Print 144T022 6 +/- 0.8

Cutout width 40 Print 144T022 6 +/- 0.8

Cutout to cutout 41 Print 144T022 15 +/- 0.8

Cutout width 42 Print 144T022 6 +/- 0.8

Tab width 43 Print 144T022 6 +/- 0.8

Notch edge depth 44 Print 144T022 2X 5.2 +/- 0.8

Tab length 45 Print 144T022 2X 5.7 +/- 0.8

Notch length 46 Print 144T022 2X 9.7 +/- 0.8

Notch to notch 47 Print 144T022 41.6 +/- 0.8

Note 48 Print 144T022 2X Sharp Corner Req'd

Notch depth 49 Print 144T022 5.2 +/- 0.8

Radius 50 Print 144T022 2X R1 +/- 0.8

Note 51 Print 144T022 Sharp Corner Req'd

Part Number 52 Print 144T022 1441677-A

Ref core dim. header to header 53 Print 144T022 837 +/- 0.8

X Requirement 54 Print 144T022 No

Radius to radius ("A" dim) * 55 Print 144T022 * 843.3 +0.5 -1.2

Datum C to end tab ("B" dim) 56 Print 144T022 858.3 +0.5 -1.2

Datum C to hole ("C" dim) 57 Print 144T022 558.3 +/- 1

Material: For CAB: Aluminum 2.0

Note 1 58 Print 144T022 thick AA 3003 with 4343 1-side

clad 4%

*Denotes this dim to be monitored

Note 2 59 Print 144T022

by vendor control plan

Rev Level 60 Print 144T022 K

Standard 61 Print 144T022 ASME Y14.5M 2009

Material Spec 62 Print 144T022 TR-AL-61

Print Number 63 Print 144T022 144T022

MV Inspect parts Master sample 144T022

white label with qty and part# date

Pack and Label customer P.O.

label attached to part.

Ship to customer E.D.I. Customer P.O. Parts customer ordered shipped.

P&G Steel Products Co., Inc

54 Gruner Road Potential Failure Mode and Effects Analysis

Buffalo, New York 14227 (PROCESS FMEA) FMEA Number: FM- 1441677-A

(716) 896 - 7900

Item: 1441677-A Process Responsibility: P&G Stamping Prepared by: Brian Riemer (Quality Manager)

Customer: TitanX Engine Cooling Key Date: 3/10/2020 FMEA Date (Orig.): 3/10/2020 (Rev.): A

Core Team: Scott Bauer (Engineering), Brian Riemer (Quality Manager), Kevin Bartosiewicz (Engineering)

C O D Action Results

Process S L Potential Cause(s) / C E R.

Potential Failure Potential Effect(s) of Current Process Current Process Recommended Responsibility

Function/ E A Mechanism(s) / of C T P. S O D R.

Mode Failure V S U Controls Prevention Controls Detection E N. Actions & Target Date Actions

Requirements Failure E C E P.

S R C Taken

V C T N.

Operation 01 Material properties Part will not meet Material ordered Procedures for purchase Incoming material

Receiving not to spec specification, material incorrectly 2 order assurance inspection compares P.O. 4 48 N/A

Inspection replacement delay to operation sheet

6

Inadequate material Certification required with Incoming Inspection

control at supplier 2 every shipment Instructions 4 48 N/A

Incorrect material Improper form, material Inadequate process Supplier process controls Incoming Inspection

thickness replacement delay 6 control at supplier. 2 and certifications Instructions 4 48 N/A

Incorrect material Improper form, material Inadequate process Supplier process controls Stock guides in die

width - too narrow replacement delay 6 control at supplier. 2 and certifications prevent material that is 4 48 N/A

too wide

Incorrect material Improper form, tooling Inadequate process Supplier process controls Stock guides in die

width - too wide adjustment 6 control at supplier. 2 and certifications prevent material that is 4 48 N/A

too wide

Material is scratched Part will not meet Inadequate process Supplier process controls Incoming Inspection

or scored specification 6 control at supplier. 2 and certifications Instructions 4 48 N/A

Material is wavy Part will not meet Inadequate process Supplier process controls Incoming Inspection

specification for flatness 6 control at supplier. 2 and certifications Instructions 4 48 N/A

Material surface is Part will not meet Inadequate process Supplier process controls Incoming Inspection

contaminated specification for 6 control at supplier. 2 and certifications Instructions 4 48 N/A

cleanliness

Cladding Material not clad, material Inadequate process Incoming Inspection

replacement delay control at supplier. Supplier process controls Instructions

6 2 4 48 N/A

and certifications

Material clad on wrong Inadequate process Certification required with Incoming Inspection

side 3 control at supplier 2 every shipment. Instructions 5 30 N/A

Material clad on both Inadequate process Certification required with Incoming Inspection

sides, material 2 control at supplier 4 every shipment. Instructions 6 48 N/A

replacement delay

Weight received Material will not produce Material ordered Procedures for purchase Incoming material

incorrect enough parts 2 incorrectly 4 order assurance inspection compares P.O. 6 48 N/A

to operation sheet

Inadequate material Certification required with Incoming Inspection

2 control at supplier 4 every shipment Instructions 6 48 N/A

OCC - Occurrence SEV - Severity DET - Detection RPN - Risk Priority Number CLASS - Classification Page 12 of 29

Operation Damaged material Part will not meet Material is dropped Forklift training in the safe Visual inspection by

02 specification, material 3 handling and preservation operator 7 84 N/A

replacement delay of material

Aluminum 4

Storage Material sustains fork Coil steel is stored in Visual inspection by

damage 3 areas away from main operator 7 84 N/A

aisles and high traffic

areas

Cannot locate Missed customer delivery Material is placed is wrong Material storage locations Visual inspection by

material when 4 location 2 are specified in plant operator 6 48 N/A

needed layout

Surface Scrap some or all material Material is subjected to Material stored in Visual inspection

contamination 4 dirt and/or moisture 2 protected areas 6 48 N/A

Operation Crimp form height not Part will not assemble Improper feed Set up instructions and In process inspection

03 even properly 3 4 first piece instructions instructions 2 24 N/A

Stamp Part off center Part will not assemble Stock guides and/or Set up instructions and In process inspection

plateside properly 3 feeder 2 first piece instructions instructions 2 12 N/A

Missing dimples Part will not assemble Incorrect changeover Set up instructions and In process inspection

properly 6 2 first piece instructions instructions 6 72 N/A

Uneven leg heights Part will not assemble Stock guides and/or Set up instructions and In process inspection

properly 3 feeder 2 first piece instructions instructions 2 12 N/A

Part depth not to Part will not assemble Ram not set to proper Set blocks on die Set up records

specification properly 8 height 3 2 48 N/A

Mis-hit, excessive die Set up instructions and In process inspection

8 wear 3 first piece instructions instructions 2 48 N/A

Part not flat Part will not assemble Incorrect roller settings Set up instructions and In process inspection

properly 3 2 first piece instructions instructions 2 12 N/A

Camber in material Set up instructions and In process inspection

3 1 first piece instructions instructions 2 6 N/A

Hole locations not to Part will not assemble Ram not set to proper Set up instructions and In process inspection

specification properly 6 height 3 first piece instructions instructions 2 36 N/A

Improper material Receiving inspection & In process inspection

6 2 first piece instructions instructions 2 24 N/A

OCC - Occurrence SEV - Severity DET - Detection RPN - Risk Priority Number CLASS - Classification Page 13 of 29

Operation Improper packaging Bent or damaged parts Operator did not follow Operation sheet and dock

04 4 packaging instructions 2 audits 1 8 N/A

Packaging

Operation Handling and Improper fit and function Use of wrong container or Operation sheet and work Final audit

05 / 06 shipping damage 4 too many pieces in 3 instructions 7 84 N/A

Storage & container

Shipping

Handling and Improper fit and function Improper handling and/or Forklift training in the safe Final audit and operation

shipping damage 4 stacking of containers 3 handling and preservation sheet 7 84 N/A

of material

Inadequate Customer rejection Operator did not follow in- Operation sheet and work Final audit

information on label 3 process inspection 2 instructions 5 30 N/A

instructions

Container mislabeled Customer rejection Operator did not follow in- Operation sheet and work Final audit

4 process inspection 3 instructions 7 84 N/A

instructions

Mixed parts or lots Customer rejection Operator did not follow in- Operation sheets, work In-process inspection and

4 process inspection 3 instructions & training final audit 7 84 N/A

instructions

OCC - Occurrence SEV - Severity DET - Detection RPN - Risk Priority Number CLASS - Classification Page 14 of 29

INITIAL SAMPLE INSPECTION REPORT

CUSTOMER

TitanX Engine Cooling Plateside PART

NO 1441677-A

REVISION

A Units MM INSPECTOR

SJM DATE

6/4/2020

Accepted

Conforming

Conforming

Rejected

P&G’s

Critical

Customer

Item

Non-

Non-

Specification

Results

Results

1

18.9 +/- 0.8 19.42

2

7.5 +/- 0.8 7.95

3

R3 +/- 0.8 ok

4

13.7 +/- 0.5 13.23 - 13.66

5

5.5 +/- 1 5.25 - 5.60

6

5.7 +/- 1 6.12

7

R3 +/- 0.8 ok

8

10 +/- 0.8 9.37 - 10.35

9

u 0.2 .11

10

2X R1.5 +/- 0.8 ok

11

52 +/- 0.8 51.91 - 52.18

12

0.4 +/- 0.15 0.30 - 0.53

13

26 +/- 1 25.95

14

n10 +/- 0.8 10.08, 10.14

15

14X 15 +/- 0.8 14.62 - 15.05

16

558.3 +/- 1 558.8

17

need to request +1.0/ -1.2

858.3 +0.5 -1.2 858.78 based on existing tooling

18

2X 88.5 +/- 0.8 88.42, 88.30

19

2X 150 +/- 0.8 150.48, 149.99

20

8X 30~ +/- 1~ 0' N/A

21

4X 15.4 +/- 0.8 N/A

22

308.7 +/- 0.8 306.3 x die makes as had

23

131.9 +/- 0.8 N/A

24

131.9 +/- 0.8 N/A

25

10 +/- 0.8 9.37 - 10.35

26

* * 843.3 +0.5 -1.2 842.72

27

0.2 / 100 ok

28

c 1 0.62

29

12 +/- 0.8 11.84, 11.79

30

9 +/- 0.8 9.09, 8.87

31

2 X 2.5 +/- 0.8 2.50, 2.61

32

2 X 7 +/- 0.8 7.45, 7.54

15 of 29

33

2 X 19 +/- 0.8 19.23, 19.38

34

2 X 5.5 +/- 0.8 5.57, 5.90

35

2 X 2 +/- 0.3 1.89, 1.94

36

2X R Full ok

37

25.9 +/- 0.8 26.32

38

2X 6.5 +/- 0.8 6.6, 6.7

39

6 +/- 0.8 6.00

40

6 +/- 0.8 6.05

41

15 +/- 0.8 15.06

E ONLY.

ARE FOR REFERENC

42

6 +/- 0.8 6.05

ALL PRINTED COPIES IC COPY FOR MOST UP TO

43

6 +/- 0.8 5.99 REFER TO ELECTRON FORMATION.

DATE IN w link to obtain

44

2X 5.2 +/- 0.8 4.99, 5.09 pervisor, Quali ty Department or follo

Contact Su

45

2X 5.7 +/- 0.8 5.52, 5.69

46

2X 9.7 +/- 0.8 9.67, 9.69

47

41.6 +/- 0.8 41.89, 42.11

48

2X Sharp Corner Req'd Conforms

49

5.2 +/- 0.8 4.99, 5.09

50

2X R1 +/- 0.8 ok

51

Sharp Corner Req'd Conforms

52

1441677-A Conforms

53

837 +/- 0.8 Ref

54

No Conforms

55

* * 843.3 +0.5 -1.2 842.72

56 need to request +1.0/ -1.2

858.3 +0.5 -1.2 858.78 based on existing tooling

57

558.3 +/- 1 558.8

58 Material: For CAB: Aluminum 2.0

thick AA 3003 with 4343 1-side 2.01

clad 4%

59

*Denotes this dim to be monitored

by vendor control plan Conforms

60

K Conforms

61

ASME Y14.5M 2009 Conforms

62

TR-AL-61 Conforms

63

144T022 144T022

16 of 29

Control Plan

Prototype Pre-launch x Production Key Contact/Phone B. Riemer 716-896-7900 X 225 Date (Orig.) 3/10/20 Date (Rev.) 3/10/20

Control Plan Number CPTEC144T022

Part Number/ 1441677-A Core Team Scott Bauer, Brian Riemer, Kevin Bartosiewicz Customer Engineering Approval Date

Latest Change Level K

Part Name Plateside Supplier Approval Date Customer Quality Approval Date

Supplier: P&G Steel Products Co. Supplier Code: 47606 Other Approval Date (if req.) Other Approval Date (if req.)

Characteristics Methods

Reaction Plan

Part Operation Machine, Special Evaluation

Number Description Device Jig, Tool No. Product Process Char. Product Specification/ Tolerance Measurement Sample Control Method

for Mfg. Class Technique

Size Freq.

1441677-A Receiving Tow motor Per Reject return to

Material tag Receiving Must match shipper Visual 1 pc.

Shipment

P.O Approval

Vendor

P.O.

Per Reject return to

Computer Material Weight Receiving Must match shipper Visual 1 pc.

Shipment

P.O Approval

Vendor

Per Reject return to

Material thickness Receiving 2.0 Thick Micrometers 1 pc.

Shipment

P.O Approval

Vendor

Per Reject return to

Material Cert Receiving AA 3003 with 4343 1-side clad 4% Visual 1 pc.

Shipment

P.O Approval

Vendor

Pull Traveler Every BOM - wrong

Verify part to Visual, compare to Verify part and replace

Components and part 2 traveler

1 pc

ISIR sample

1 pc. setup / bracket will not fit with correct part

reset weld fixture

from moving

Material Per Reject return to

inventory equipment. Receiving No dirt oil road crud, white or red rust. Visual 1 pc.

Shipment

P.O Approval

Vendor

cleanliness

Stamp End tab to center

1

of radius

Production 18.9 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

End tab to center

2

of radius

Production 7.5 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

3 Radius Production R3 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

4 Datum A to tab Production 13.7 +/- 0.5 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Per start- First piece Red tag issued to

5 Tab height Production 5.5 +/- 1 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

End tab to center

6

of radius

Production 5.7 +/- 1 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

7 Radius Production R3 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

8 Leg Height Production 10 +/- 0.8 CMM / Height gage 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Per start- First piece Red tag issued to

9 Straightness Production u 0.2 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

10 Radius Production 2X R1.5 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

11 Part width Production 52 +/- 0.8 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Per start- First piece Red tag issued to

12 Dimple height Production 0.4 +/- 0.15 CMM /Height Gage 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

13 Dimple to dimple Production 26 +/- 1 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

14 Hole Diameter Production n10 +/- 0.8 CMM / Pin gage 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

15 Dimple length Production 14X 15 +/- 0.8 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Datum C to hole

16

("C" dim)

Production 558.3 +/- 1 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

Datum C to end

17

tab ("B" dim)

Production 858.3 +0.5 -1.2 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Datum C to tab

18

end

Production 2X 88.5 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Datum C to end

19

tab

Production 2X 150 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

20 N/A Production 8X 30~ +/- 1~ 0'

21 N/A Production 4X 15.4 +/- 0.8

Datum C to

22

centerline

Production 308.7 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

23 N/A Production 131.9 +/- 0.8

24 N/A Production 131.9 +/- 0.8

Per start- First piece Red tag issued to

25 Leg Height Production 10 +/- 0.8 CMM / Height gage 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Per start- First piece Red tag issued to

Radius to radius

26

("A" dim)

Production * * 843.3 +0.5 -1.2 CMM 1 pc. up and

restart

approval CMM

Data

operator & MRD for any

non-conforming material

Per start- First piece Red tag issued to

CMM / Feeler

27 Flatness Production 0.2 / 100 Gage

1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

Per start- First piece Red tag issued to

CMM / Feeler

28 Flatness Production c 1 Gage

1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

End tab to middle

29

tab

Production 12 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

30 Middle tab width Production 9 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

31 Cutout width Production 2 X 2.5 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

32 End tab width Production 2 X 7 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

33 Edge to cutout Production 2 X 19 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

34 Edge to tab Production 2 X 5.5 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

35 End tab length Production 2 X 2 +/- 0.3 CMM 1 pc. up and approval CMM operator & MRD for any

restart Data non-conforming material

36 Radius Production 2X R Full CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

37 End tab to radius Production 25.9 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Part edge to tab

38

edge

Production 2X 6.5 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

39 Tab width Production 6 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

40 Cutout width Production 6 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

41 Cutout to cutout Production 15 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

42 Cutout width Production 6 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

43 Tab width Production 6 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

44 Notch edge depth Production 2X 5.2 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

45 Tab length Production 2X 5.7 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

46 Notch length Production 2X 9.7 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

47 Notch to notch Production 41.6 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

48 Note Production 2X Sharp Corner Req'd Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

49 Notch depth Production 5.2 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

50 Radius Production 2X R1 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

51 Note Production Sharp Corner Req'd Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

52 Part Number Production 1441677-A Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

Ref core dim.

53

header to header

Production 837 +/- 0.8 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

54 X Requirement Production No Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

Per start- First piece Red tag issued to

Radius to radius

55

("A" dim)

Production * * 843.3 +0.5 -1.2 CMM 1 pc. up and

restart

approval CMM

Data

operator & MRD for any

non-conforming material

Datum C to end

56

tab ("B" dim)

Production 858.3 +0.5 -1.2 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Datum C to hole

57

("C" dim)

Production 558.3 +/- 1 CMM 1 pc. At PPAP PPAP approval Resubmit PPAP

Material: For CAB: Aluminum 2.0

58 Note 1 Production thick AA 3003 with 4343 1-side Certification 1 pc. At PPAP PPAP approval Resubmit PPAP

clad 4%

*Denotes this dim to be monitored

59 Note 2 Production Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

by vendor control plan

60 Rev Level Production K Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

61 Standard Production ASME Y14.5M 2009 Standard 1 pc. At PPAP PPAP approval Resubmit PPAP

62 Material Spec Production TR-AL-61 Material cert 1 pc. At PPAP PPAP approval Resubmit PPAP

63 Print Number Production 144T022 Visual 1 pc. At PPAP PPAP approval Resubmit PPAP

Pack and Label Cartons and Red tag issued to

Per instruction

printer Qty per container Set-up per shipping order Visual 1 pc. per shift /traveler sheet

operator & MRD for any

non-conforming material

Red tag issued to

per computer

Label information Set-up per approved TitanX scanned 1 pc.

container generated

operator & MRD for any

non-conforming material

Red tag issued to

Shipping EDI P.O. per

Ship Set-up Customer order CMM 1 pc.

shipment

Shipping approval operator & MRD for any

non-conforming material

Data Sheet

Reference CMM Program for these dimensional checks.

Part Name: Plateside Document # : DSTE- 1441677-B Doc. Revision: A

Part Number: 1441677-A Print Revision: K 10/21/2019 Shop Order # :

Inspection Frequency ___1 time set-up and restart________________________

4 5 8 9 11 12 15 17 *26 27 28 35

14X (15) 858.3 +0.5 843.3 +0.5 2X 2

13.7 +/- 0.5 5.5 +/- 1 10 +/- 0.8 u 0.2 52 +/- 0.5 0.4 +/- 0.15 0.2 / 100 c 1 Clad Side Date Insp.

+/- 0.8 -1.2 -1.2 +/- 0.3

.

R E FOR R EF ERENCE ONLY

COPIES A ST UP TO

ALL PRINTED ECTRONIC COPY FOR MO

REFER TO EL DATE INFORMATION. llow link to obtain.

or fo

or, Q u ality Department

rvis

Contact Supe

19 of 29

P&G Steel Products Co.,

Inc.

54 Gruner Road

Buffalo, New York 14227

(716) 896-7900 Phone PART SUBMISSION WARRANT

(716) 896-4129 Fax

Part Name Plateside Cust. Part Number 1441677-A

Shown on Drawing No. 144T022 Org. Part Number 1441677-A

Engineering Drawing Change Level K Dated 10/21/2019

Additional Engineering Changes Dated

Safety and/or Government Regulation Yes x No Purchase Order No. Weight (kg)

Checking Aid No. N/A Checking Aid Engineering Change Level N/A Dated N/A

ORGANIZATION MANUFACTURING INFORMATION CUSTOMER SUBMITTAL INFORMATION

P&G Steel Products Company, Inc. 47606

TitanX Engine Cooling

002104800

Supplier Name & Supplier/Vendor Code Customer Name/Division

54 Gruner Road Kelly Snyder

Street Address Buyer/Buyer Code

Buffalo NY 14227 DTNA M2 Long

City State Zip Application

MATERIALS REPORTING

Has customer required Substances of Concern information been reported?. X Yes No n/a

Submitted by IMDS or other customer format: 789118240/0.01

Are polymeric parts identified with appropriate ISO marking codes? Yes No X n/a

REASON FOR SUBMISSION

x Initial Submission Change to Optional Construction or Material

Engineering Change(s) Sub-Supplier or Material Source Change

Tooling: Transfer, Replacement, Refurbishment, or additional Change in Part Processing

Correction of Discrepancy Parts Produced at Additional Location

Tooling inactive > than 1 year Other – Please specify

REQUESTED SUBMISSION LEVEL (Check one)

Level 1 – Warrant only (and for designated appearance items, an Appearance Approval Report) submitted to customer.

Level 2 – Warrant with product samples and limited supporting data submitted to customer.

Level 3 – Warrant with product samples and complete supporting data submitted to customer.

X Level 4 – Warrant and other requirements as defined by customer. 1,5,6,7,9,10,14,18

Level 5 – Warrant with product samples and complete supporting data reviewed at supplier’s manufacturing location.

SUBMISSION RESULTS

The results for dimensional measurements x material and functional tests appearance criteria Statistical process package

These results meet all drawing and specification requirements: Yes x No (If “NO” - Explanation Required)

Mold / Cavity / Production Process Stamping

DECLARATION

I affirm that the samples represented by this warrant are representative of our parts, which were made by a process that meets all Production Part

Approval Process Manual 4th Edition Requirements. I further affirm these samples were produced at the rate of 150pcs / _hour.

I also certify that documented evidence of such compliance is on file and available for review. I have noted any deviations from this declaration below.

EXPLANATION/COMMENTS: Tooling was transferred from Wayne Metals

Is each Customer Tool properly tagged and numbered? X Yes No

Organization Authorized Signature Date 6/15/2020

Print Name Brian Riemer Phone No. (716) 896-7900 x 225 Fax No. (716) 896-4129

Title Quality Manager Email briemer@[Link]

FOR CUSTOMER USE ONLY (IF APPLICABLE)

Part Warrant Disposition: X Approved Rejected Other

Customer Signature Date 7/28/2020

Print Name Robert Hoden TitanX SQAD Manager Customer Tracking Number (optional)

Sample parts

Part number Drawing number Issue-level

1441677-A 144T022 K

Supplier name Part description

P&G Steel Plateside

Production date Quantity produced

3/10/2020 10

Batch number Quantity delivered

10

Production Process:

Fabrication

Parts produced with a serial process configuration: Yes ✘ No

Tooling used:

None

Tooling with several cavities (mold…): Yes ✘ No

If YES, inspection results will done on each cavity

- Added points:

Several tooling avliable and qualified: Yes ✘ No

If Yes, one PPAP submission for each tooling

- Added Points:

The supplier will keep:

At least 2-5 master samples for 15 years on his premises

✘ 1 sample during the product warranty time

No sample during the product warranty time

Material Certificate

Logistic and packaging validation

(packaging instruction sheet + label on packaging

Partnumber Description Date Issue

1441677-A Plateside 3/10/2020

Drawing Issue Issuer Pallet flag

144T022 K P&G Steel

Packing/Pallet Pallet collars Masonite Lid Carton Quantity

Valeo Tote 30

Additional information, such as number of parts per layer etc…

30 pcs per TitanX green tote (weight must not exceed 35lbs)

Picture

Insert photo / photo´s of essential tooling

used to produce the part Tooling

Tool no/Indentification Application No of tools Photo no 1

2

Tooling drawings including spare part list

Defect Catalogue

Report into IMDS database

id-marking

You might also like

- FIT-WI-2205-QCP-001 V1.0 贴片QC工程图 zh-CN to en 2024-09-09 10-50-05engNo ratings yetFIT-WI-2205-QCP-001 V1.0 贴片QC工程图 zh-CN to en 2024-09-09 10-50-05eng6 pages

- INJECTOR PORT LH & RH REV 2 - Plano de Inyector de CombustibleNo ratings yetINJECTOR PORT LH & RH REV 2 - Plano de Inyector de Combustible1 page

- Defect History and FMEA Analysis ReportNo ratings yetDefect History and FMEA Analysis Report22 pages

- Potential Failure Mode and Effects Analysis (Design FMEA)No ratings yetPotential Failure Mode and Effects Analysis (Design FMEA)12 pages

- PFMEA-240-099-M02E-GLX-R0 - To Be Reviewed Against The Top CoverNo ratings yetPFMEA-240-099-M02E-GLX-R0 - To Be Reviewed Against The Top Cover3 pages

- Manufacturing and Inspection Plan for MotorsNo ratings yetManufacturing and Inspection Plan for Motors5 pages

- Failure Mode and Effects Analysis - ReportNo ratings yetFailure Mode and Effects Analysis - Report13 pages

- GM 1927 16b Stamping Process Audit-GM ConfidentialNo ratings yetGM 1927 16b Stamping Process Audit-GM Confidential6 pages

- Manufacturing Process Excellence Handout (J Bero)No ratings yetManufacturing Process Excellence Handout (J Bero)38 pages

- 2330859-7 - 415664 - SG - AgC v5 - Process Flow ChartNo ratings yet2330859-7 - 415664 - SG - AgC v5 - Process Flow Chart1 page

- 001 - Technical Feasibility Eturna End Cap - Stage 1 - 25apr2024No ratings yet001 - Technical Feasibility Eturna End Cap - Stage 1 - 25apr202460 pages

- Action Plan With Closer Sheet - Enco 09.09.2025No ratings yetAction Plan With Closer Sheet - Enco 09.09.20254 pages

- Notice: Self-Regulatory Organizations Proposed Rule Changes: Nasdaq Stock Market LLCNo ratings yetNotice: Self-Regulatory Organizations Proposed Rule Changes: Nasdaq Stock Market LLC2 pages

- Operating Procedure Compensation For Wrongful DisconnectionNo ratings yetOperating Procedure Compensation For Wrongful Disconnection18 pages

- Risk Management: Presentasi Untuk: PT - Truba Jurong EngineeringNo ratings yetRisk Management: Presentasi Untuk: PT - Truba Jurong Engineering18 pages

- "The Goal Book Review: Manufacturing Insights"No ratings yet"The Goal Book Review: Manufacturing Insights"1 page

- All Academia - Saving Bank Product PPT - 09052019100% (1)All Academia - Saving Bank Product PPT - 09052019138 pages

- Introduction of Book Keeping & AccountancyNo ratings yetIntroduction of Book Keeping & Accountancy33 pages

- Anam - 1195 - 15793 - 1 - Chap 1 - Technology-Driven Consumer Behavior100% (1)Anam - 1195 - 15793 - 1 - Chap 1 - Technology-Driven Consumer Behavior11 pages

- A Technically Competent, Multi-Disciplinary& Professionally QualifiedNo ratings yetA Technically Competent, Multi-Disciplinary& Professionally Qualified2 pages