Follow Health,

Safety and Security

Procedures

Topics

1. Occupational Safety & Health

2. Reporting and Recording

3. Personal and Environmental

Hygiene

4. Risk Assessment and Hazard

Management

5. Types of Hazards

6. Emergencies

7. Fires

8. First Aid

Occupational Safety

and Health

Occupational Safety & Health

OSH concerns safety, health and

welfare of people in the work place.

It aims to protect people who might be

indirectly related to the workplace

environment, like family members of

employees, employers, and customers.

There are many different types of costs

associated with workplace injuries;

many of them are not just physical.

Therefore it is important to understand

these costs and risks and formulate

adequate and effective policies and

procedures.

Objectives of OSH

1. Identify occupational hazard

2. Reduce workplace accidents

3. Eliminate (where possible) health

and safety risk at work place

4. Protect personnel against

occupational hazard

5. Manage health and safety concerns

6. Involve all parties concerned in

OHS management and creating

awareness

Code of Practice

These are a set of guidelines of conduct

but not a legal regulation.

These codes of practices are generally

issued by regulatory authorities to meet

OHS obligations.

They provide for a number of options

and give guidance for employers and

individuals to meet OHS standards.

Most organizations have a Code of

Conduct policy for their staff.

OSH Responsibilities

In the workplace it is the employer who

has the duty of care for OHS; although

all employees are required to assist

employers fulfil this responsibility.

Government

Duty of Care is the responsibility one

person has for another in the eyes of the

law, for that person’s health and safety.

Employers

Employers and employees have a duty

of care towards each other and the

general public.

Workers

Employer Obligations

1. Provide employees with adequate

4. Ensuring that the way work is

information, and training to

done is safe and does not affect

perform their job safely

employees’ health.

2. Maintaining equipment used by

5. Involving employees and / or

staff, training for use of the

worker representatives in health

equipment and ensuring safe

and safety initiatives in the

systems of work.

workplace

3. Ensuring that the ways of storage,

6. Monitoring, recording and

handling and use of hazardous

evaluating workplace incidents.

substances are safe.

Employee Duties

1. Take reasonable care for their own

health & safety and that of anyone

else who may be affected.

2. Co-operate with employers to

comply with the requirements

imposed by or under the Act.

3. Report breaches of safety and

potential risks.

4. Work and behave in ways that are

safe.

5. Follow instructions imposed by the

employer that are legal.

Creating a Safe Work Place

Aspects that need to be focused on to

make the workplace safe are;

1. Design

2. Layout -

Space and Workflow

3. Structure -

Floors, Stairs, Doors and Windows

4. Services -

Ventilation, heating, lighting

5. Maintenance and housekeeping

Policies and Procedures

Policy

The position or stand that an

organization or an individual takes on an

issue. It is acceptable patterns of

behavior and practices in a workplace.

Procedures

The steps involved in carrying out a task

or duty. These are clear directions and

instructions to carry out a task in

step-by-step manner or specific action

to be taken in the event of

emergencies.

Reporting and Recording

Reporting and Recording

Although we strive to prevent accidents

we must have procedures in place for

reporting and recording details if an

event takes place.

After calling the ambulance or

administering first aid a written report

must be submitted to the employer.

Even a near miss must be reported!!

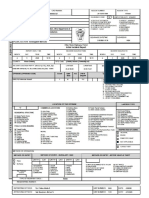

Reporting of Injuries, Disease and Dangerous Occurrences

Regulation - RIDDOR

RIDDOR is the law that requires employers, and other people in control of work

premises, to report and keep records of:

1. Work-related accidents which cause death

2. Work-related accidents which cause certain serious injuries

3. Diagnosed cases of certain industrial diseases

4. Certain ‘dangerous occurrences’ (incidents with the potential to cause harm).

Incidents Other than Accidents

that Need to be Reported

1. Verbal abuse

2. Threats

3. Assault

4. Anything that could lead to a serious

hazardous situation

Why Should We Report?

1. Investigation to assess risks.

2. Analysis to determine the reasons.

3. Prevention to reduce risks.

Procedure to Report an

Incident

The incident should be;

1. Recorded

2. Investigated

3. Risk-assessed

4. Control measures introduced

5. Reviewed

Information to be Recorded

1. Date

2. Time

3. Name of person recording

4. Brief description of accident

5. Witnesses

6. Action taken by whom

7. Result

Personal and

Environmental Hygiene

Policies and Procedures

Customers have the right to expect the

business to be free from pests and the

staff to be clean and healthy.

Clean glasses, utensils, rooms, and

linen, good quality and safe food and

beverage that will not make them sick.

If these are not provided, the business

will soon not have any customers to

service.

Personal Hygiene

The human body harbors germs and bacteria. The following is a list which will

ensure that the highest standards of hygiene are met;

1. Take daily showers.

6. Have clean, tidy hair tied back

and covered in food prep area.

2. Wear clean and ironed clothes.

7. Know when and how to wash

3. Limit the jewellery that you wear

your hands.

4. Clean your teeth regularly and

8. Perform your job in a clean and

ensure they are in good condition.

tidy manner and follow all work

place cleaning procedures.

5. Keep any open cuts and wounds

covered by using waterproof cover

9. Have short, clean nails with no

over a band aid or bandage.

nail polish.

Environmental Hygiene

1. Regularly clean the premises.

2. Control pests and vermin.

3. Implement a daily cleaning

schedule and clean equipment.

4. Maintain F&B service areas.

5. Follow correct storage and

garbage removal procedures.

6. Follow workplace “No Smoking”

requirements.

7. Follow clean as you go policy.

Risk Assessment and

Hazard Management

Hazard vs Risk

Hazard refers to anything having

Risk is the likelihood that a potential

potential to cause harm.

hazard will result in injury or disease.

1. Hazard management is the

1. The risk must also be measured in

identification of hazards in the

terms of the extent of injury that

workplace that poses a potential

may result.

threat and the implementation of

steps to eliminate those hazards.

2. Risk control is an employer

obligation, it means eliminating or

2. Hazards exist everywhere; what

reducing the likelihood of injury

action you take now may prevent

that could result from exposure to

your own injury.

the hazard.

Causes of Hazards

1. Poor design

6. Distraction and lack of attention.

- Bad infrastructure in building.

7. Working too quickly.

2. Poor signage.

8. Ignoring rules.

3. Bad housekeeping standards.

9. Not wearing PPE

4. Poor lighting or ventilation.

- personal protective equipment

5. Dangerous working practices.

10. Physical/mental state.

Minimizing Risk of Hazards

Risks are expressed as the likelihood of getting injured, whereas hazard refers to

the agent responsible. To minimize the risk of hazards we must have:

1. Improved and safe design of

5. Training staff in work practices.

building.

6. Reporting procedures, strict

2. Correct and clear/visible signage.

enforcement of rules.

3. Good housekeeping standard.

7. Correct use of PPE at all times.

4. Well lit and ventilated working

8. Physically/mentally ready to

areas.

work.

Steps in Risk Assessment

1. Identify all hazards.

2. Identify who is at risk.

3. Evaluate risks.

4. Implement control measures.

5. Record the assessment.

6. Review of steps.

Benefits of Risk Assessment

1. Prevents accidents and ill health.

2. Prioritises actions which improve

operational efficiency.

3. Financial savings.

4. Confidence in health and safety

measures.

5. Legal compliance.

Control Measures Against

Hazards

1. Remove or eliminate hazards.

2. Separate or isolate worker from

hazards.

3. Develop and use safe systems of

work, training, instruction and

supervision of workers.

4. Provide personal protection to

minimise risk.

Types of Hazards in the

Work Place

Types of Hazards

1. Physical Hazards

2. Chemical Hazards

3. Manual Handling Hazards

4. Psychological Hazards

5. General Hazards

Physical Hazards

Physical Hazards are those that have an

impact on the body through noise &

vibration, heat & cold.

Fatigue and lack of concentration which

can result in injury.

Industrial deafness - Caused by a result

of exposure to noise hazards in the

workplace.

Ways Machinery / Equipment can Cause Injuries

1. Entanglement/entrapment

2. Impact

From falling equipment

3. Contact

4. Faulty equipment

5. Inappropriate use of equipment

Control Measures to Prevent Injury

1. Training in the use of equipment

2. Using Personal Protective

Equipment (PPE)

3. Safe working procedures

4. Report faults

Chemical Hazards

Chemicals become dangerous from use

and misuse as a result of: -

1. Spillage

2. Handling

3. Leakage

4. Inhalation

5. Consumption

6. Incorrect Storage.

Types of Chemical Hazards

The nature of a chemical dictates how it

can affect us if mishandled.

1. Poisonous -

Toxic – ammonia

2. Corrosives can burn the skin –

Acid cleaners

3. Irritants can inflame the skin –

Detergents, cleaning chemicals

4. Explosive / flammable chemicals -

Gases, gels and spirits

Control Measures for Chemical Hazards

1. Training in the use of hazardous

substances.

2. Personal protective equipment

(PPE).

3. Safe working procedures.

4. Controlled distribution of

dangerous substances (chemicals)

5. Storage of chemicals separately

from food stuff.

6. Training in the use of equipment

Manual Handling

Manual handling like lifting, pulling and pushing, and carrying may result in injuries

and may pose health and safety risks, if proper OHS procedures are not followed.

Whenever manually handling things, always:

1. Assess the task

5. Ensure you have a clear path.

(distance, weight, temperature).

6. Check the environment is safe

2. Follow the correct procedure

(flooring, lighting and

(minimize the distance, correct

temperature, free from

number of people, correct

obstructions).

lifting/carrying equipment).

7. Ensure there is a clear place to

3. Reduce the load.

put the object.

4. Training staff in work practices.

8. Adopt the right posture.

Correct Lifting Procedure

1. Planning and preparation

Plan the lift and route, assess the

weight, size and temperature

2. Lift

Correct posture, feet shoulder

width apart, hold object close

to body

3. Move load

Hold close, clear visibility and

proceed carefully

4. Lower load

Check positioning

Manual Handling Injuries

1. Back/spinal injuries

2. Muscular injuries

3. Fractures

4. Sprains

5. Cuts

6. Bruises

Psychological Hazards

Psychological hazards are those that

impact our mental wellbeing.

The most common one is stress.

It may be caused due reduced staff

levels or pressure for increased

productivity, management change etc.

General Hazards

General hazards are the biggest cause of accidents in the workplace.

1. Poor storage and shelving

8. Poor and/or Unguarded lighting

2. Torn carpets

9. Protective clothing

3. Improperly placed safety signs

10. Incorrect use of equipment

4. Machinery without guards

11. Burns and heat related injuries

5. Sharp objects like knives

12. Cuts and wounds

6. Slippery floors

13. Slips and falls

7. Faulty or damaged equipment

14. Equipment related injuries

Personal Protective Equipment

1. Gloves to protect hands

2. Goggles and mask when using

hazardous chemicals

3. Back support when lifting weights

4. Safety shoes to protect against slips

and falls

5. Double breasted and long sleeve

cotton jackets to prevent burns

Standard Safety Signs

Hazard warning signs

Safe signs

Mandatory signs

(Triangle)

(Green)

(Blue)

Warning signs

Prohibition signs

Fire fighting signs

(Yellow)

(Red)

(Red)

Cost of Work Place Incidents

1. Human cost:

Physical Pain

2. Social cost:

Stress to family

Employer’s loss of labour

3. Financial cost:

Medical bills

Loss of pay

4. Psychological cost:

Mental trauma

Stress

Emergencies

What is an Emergency?

Emergency refers to an accident or

incident that results in or could result in

serious injury or even death. Example,

fire, explosion, etc.

Causes of Fires and Explosions

1. Electricity, electrical fault.

2. Gas leak.

3. Build up of gas.

4. Smoking.

5. Hot liquid/substances.

Emergencies Procedures

1. Moving the casualty from danger

zone (if possible)

2. Seek help from competent first

aider

3. Contact emergency services

4. Seek medical assistance urgently

Bomb Threats

These are usually made over the phone.

Take down information while Infer the following from the

speaking to the person such as;

conversation:

1. ‘who are you’

1. Determine if Male or Female.

2. ‘where is the bomb’

2. Do they have an accent?

3. ‘when will it go off’

3. Did you hear traffic or any other

background sounds?

4. ‘why are you threatening us’

4. Get information-

5. ‘what type of bomb is it’

as much as possible

Electrical Dangers

They result In;

1. Electric shock

2. Burns

3. Fire

4. Death

Measures to Prevent

Electricity Dangers

1. Testing and maintenance of

electrical equipment.

2. Use of qualified electricians.

3. Check cables and flex.

4. Use of correct fuses.

5. Circuit breakers.

6. Do not use faulty equipment.

Fires

Fires

All hospitality establishments are

covered by legislation which ensures

that;

1. All exit and fire escapes are clear

and well signed.

2. Fire extinguishers and blankets are

available and in working order

3. Exit doors clearly marked

4. Smoke and fire alarms installed

5. Have regular fire drills

Procedures to Follow During a Fire

1. Raise an alarm.

2. Switch off power.

3. Never use a lift in an emergency

4. Follow the procedures of the

establishments.

5. Call for help (first aid, ambulance)

6. Call the reception and report

the fire.

7. Follow legal requirements.

Firefighting

Firefighting is the act of extinguishing

fires to prevent loss of life, and

destruction of property and the

environment.

Firefighting is a well-trained technical

skill that requires training in both

specialized and general fire fighting

techniques.

Classes of Fire

Fire Triangle

The fire triangle or combustion triangle

is a simple model for understanding the

ingredients necessary for most fires.

The triangle illustrates a fire requires

three elements: heat, fuel, and an

oxidizing agent (oxygen).

The fire is prevented or extinguished by

removing any one of them.

A fire naturally occurs when the

elements are combined in the right

mixture.

Fire Fighting Requirements

Fire fighting requires the removal of;

1. Fuel (remove the source of fuel).

2. Oxygen (restrict the supply of

oxygen by smothering).

3. Heat (remove the heat).

Fire Fighting Equipment

1. Fire extinguishers.

2. Sand buckets.

3. Fire blankets/mineral blanket.

Fire Extinguisher

Fire extinguisher, flame extinguisher, or

simply an extinguisher, is a device used

to extinguish or control small fires,

often in emergency situations.

It is not intended for use on an

out-of-control fire, such as one which

has reached the ceiling, endangers the

user.

Typically, a fire extinguisher consists of a

hand-held cylindrical pressure vessel

containing an agent which can be

discharged to extinguish a fire.

Types of Extinguishers

Water or Air Pressurized Water Fire

Extinguisher -

Recommended for fires caused from

wood, paper, textile, and solid material

fires.

CAUTION for APW Fire Extinguishers -

is DO NOT USE on liquid, electrical or

metal fires.

Dry Powder Fire Extinguisher -

Is recommended for fires caused from

liquid and electrical fires.

CAUTION for Powder Fire Extinguisher

is DO NOT USE on metal fires.

Types of Extinguishers Cont.

Foam Fire Extinguisher -

Recommended for fires caused from

liquid fires.

CAUTION for Foam Fire Extinguishers

is DO NOT USE on electrical or metal

fires.

Carbon Dioxide Fire Extinguisher –

Recommended for fires caused from

liquid and electrical sources.

CAUTION of Carbon Dioxide Fire

Extinguisher is DO NOT USE on metal

fires.

Assembly Point

In case of fire immediately raise an

alarm, inform others and evacuate in an

orderly manner.

Assemble outside the building and call

civil defense (997) or applicable number

for assistance.

The Fire assembly point is generally

outside the main entrance of the

building and stand a minimum of 20

feet away from the building.

First Aid

First Aid in the Workplace

Legislation requires employers to

provide adequate facilities for the

welfare of employees.

Therefore the employer is obliged to

make available facilities for the

administration of first aid.

First Aid can be defined as the

application of emergency care, in the

first instance to an injury.

Sometimes this may be a temporary

measure before removal to hospital or

attendance by a doctor.

Burns - Precautions and First Aid

This is a common kitchen injury and should be treated immediately

Preventive Measures

Don’ts

1. Use Protective clothing and

1. Touch affected area.

equipment - tea towels, oven

2. Burst blisters

gloves, cotton uniform.

3. Remove anything sticking

2. Use trolleys to carry hot things.

Dos

3. Follow SOPs.

1. Cool the affected area- hold

under cold running water (10min)

4. Use goggles and gloves when

2. If eyes – rinse with cold water

handling chemicals.

3. If chemical – at least 20 min.

under cold running water

Cuts - Precautions and First Aid

This is the most common kitchen injury and should be treated correctly

Precautions

First aid

1. Use the correct knife

1. Press the cut to stop bleeding

2. Use a sharp knife; a blunt knife

2. Hold it higher than heart level

will slip and cause injury

3. Dress it with sterile cotton

3. Handle correctly

dressing

4. Dry non greasy hands

Falls, Slips and Strains - Precautions and First Aid

Precautions

First aid

1. Wipe spills immediately

1. Do not stand up immediately or

make sudden movements

2. Clear obstructions

2. Check for broken bones, Sudden

3. Correct storage and proper

swelling is an indication of

shelving

fractures or sprains

4. Wear rubber soled shoe

3. If broken bones are suspected,

call for first aider/medical help

5. Good lighting

4. Support the suspected broken

6. Caution sign boards

bone, before moving

Electric Shock - Precautions and First Aid

Precautions

First aid

1. Proper earthling

1. Switch off the power

2. Protective covering

2. EAR

(expired air resuscitation)

3. Handling as per manufacturers

instruction

3. CPR

(cardiopulmonary resuscitation)

Poisoning - Precautions and First Aid

Precautions

First aid

1. Labeled container

1. For non-corrosive chemicals -

induce vomiting

2. To be kept under lock

2. Inhaled poison –

expose to fresh air

3. Absorption through skin -

wash the affected area