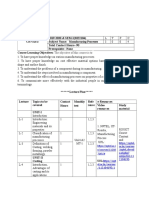

3ME07: METAL FORMING, JOINING AND FOUNDARY PRACTICES

CREDITS - 4 (LTP: 3,0,1)

Course Objective:

To illustrate technology of welding, casting and forming processes

Teaching and Assessment Scheme:

Teaching Scheme

Credits Assessment Scheme Total

(Hours per Week)

Marks

Theory Marks Practical Marks

L T P C

ESE CE ESE CE

150

3 0 2 4 60 40 20 30

Course Contents:

Unit Teaching

Topics

No. Hours

1 Introduction: 2

Objectives of a manufacturing process, Classifications of Manufacturing

Processes for metals and alloys.

2 Theory of Welding and Welding Processes: 16

Definition of a weld, a joint, Types & Parameters of weld, Types of joints,

Weldment, Welding positions,

Mechanisms of formation of weld, Metallurgical aspects of fusion and pressure

welding

Basic requirements of welding and how these requirements are fulfilled by

welding processes, Classifications of welding processes. Comparison between

welding, soldering, brazing and riveting.

Arc Welding Processes: The welding arc, Nature and Behavior of welding arc

and its relevance to the practice, Arc initiation and arc maintenance methods,

Arc welding power sources and their characteristics.

Principle of operation, characteristics, consumables, equipment, process

variables and capabilities of arc welding processes like SMAW, SAW,

GMAW, GTAW, Designing arc welding procedures.

Principle of operation, characteristics, consumables, equipment, process

variables and capabilities of processes like Resistance, LASER, Electron

Beam, Friction, Oxy-Acetylene Gas welding.

Other Joining Processes like Brazing, Soldering and Adhesive Bonding;

Thermal Cutting processes: Oxy-Acetylene gas cutting - mechanism of cutting,

effect of process variables, applications; Plasma arc cutting, LASER Beam

cutting processes.

3 Fundamentals of Metal casting and Metal casting Processes: 12

Applications of metal casting, Classification of casting processes.

Mechanism and Rate of Solidification of Metals and Alloys: Solidification of

pure metals and alloys, Factors influencing solidification of castings, Feeding

Resistance,

Gas Porosity in castings, Factors causing gas dissolution in liquid metal,

Degassing techniques.

Unit Teaching

Topics

No. Hours

Gating Design, gating ratios, Aspiration effects and its prevention, Gating

methods, Slag-Trap systems, Metal Fluidity, Factors governing metal fluidity,

Measurement of fluidity.

Feeder Design and Placement, Directional solidification in castings

Expendable Mould Production:

Pattern Construction: Types of patterns, Pattern Allowances, Design of pattern,

Moulding Material: Types of Sand, Properties, Preparation and Testing,

Moulding processes like Green sand, dry sand, CO2 moulding, Shell Moulding,

Investment casting.

Permanent Mould processes like Centrifugal casting, Pressure Die casting

Defects in castings

4 Theory of Metal Forming and Forming Processes: 12

Application of metal forming, Theory of Plastic deformation, Strain hardening,

Recovery, Recrystallization and Grain Growth, Effect of Temperature,

Composition and Strain rates on metal forming, Characteristics and

applications of Hot working and Cold working, Classification of metal forming

processes according to stresses.

Working principle, characteristic features, capabilities and application of Bulk

Metal Forming Processes like Rolling, Forging, Extrusion, Wire Drawing and

Thread Rolling.

Working principle, characteristic features, process variables, capabilities and

application of Sheet Metal Working like Shearing, Bending, Deep Drawing,

Spinning, Coining, Embossing,

Total 42

List of References:

1. Parmar, R. S., “Welding Processes and Technology”, 3rd edition, Khanna Publishers, 1996

2. Kaushish, J. P., “Manufacturing Processes”, 2nd Edition, PHI Learning Pvt. Ltd, 2010

3. Rao, P. N., “Manufacturing Technology: Volume 1 Foundry, Forming and Welding”, 5th

edition, Tata McGrawHill, 2018

4. Ghosh, Amitabh & Mullick, “Manufacturing Science”, 2nd edition, EWP, 1986.

5. Ravi, B., “Metal Casting: Computer-Aided Design and Analysis” PHI,2005

6. Flinn, R. A., “Fundamentals of Metal Casting”, Addison-Wesley

7. Houldcroft, Peter, “Welding Process Technology”, Cambridge University Press,1977

8. Cary, Howard B.,Helzer, Scott, “Modern Welding Technology”, 6th edition, Pearson, 2005

9. Kalpkjian, S, Schmid Stevens, “Manufacturing Engineering & Technology” 7th Edition,

Pearson, 2013

10. Black, J. T., & Kohser, Ronald A.; “DeGarmo’s Materials and Processes in Manufacturing”,

10th edition, John Wiley & Sons, Inc., 2007

11. Juneja, B. L., “Fundamentals of Metal Forming”, 1st Edition, New Age International (P)

Ltd.,2007

Course Outcomes (COs):

At the end of this course students will be able to …

1. Identify how the given process achieves the required shape and size along with required

properties.

2. Illustrate capabilities of welding processes and select an appropriate welding process for a

given application and hence develop a welding procedure for a given job.

3. Illustrate casting problem (melting, refining & pouring and production of a mould) and explain

process capabilities and application of casting processes. Design a “mould ready to pour”

solution for a given casting.

4. Illustrate capabilities and hence application of bulk metal forming processes and sheet metal

work.